Margin of overpull is additional tension to be applied when pulling the stuck drill string without breaking the tensile limit of the drill string. This is the difference between maximum allowable tensile load of drill string and hook load.

The formula for margin of overpull is described below;

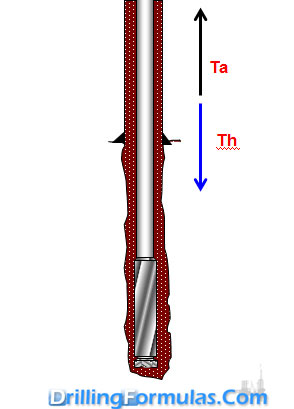

Margin of Overpull = Ta – Th

Where;

Ta is the maximum allowable tensile strength, lb.

Th is the hook load (excluding top drive weight), lb.

The ratio between Ta and Th is safety factor (SF).

SF =Ta ÷ Th

Example: The drill string consists of the following equipment:

5” DP S-135, 4-1/2” IF connection, adjusted weight of 23.5 ppf = 8,000 ft

5” HWDP S-135, 4-1/2” IF connection, adjusted weight of 58 ppf = 900 ft

Mud motor and MWD, weight 20 Klb, = 100 ft

Expected hook load at TD = 270 Klb

Tensile strength of 5” DP S-135 (premium class) = 436 Klb

Tensile strength of 5” HWDP S-135 (premium class) = 1,100 Klb

90% of tensile strength is allowed to pull without permission from town.

Determine the margin of overpull from the information above.

Maximum tension will happen at the surface so 5”DP will get the most tension when pulling and since only 90% of tensile strength is allowed. The allowable tensile (Ta) is as follows;

Ta = 0.9 x 436 = 392 Klb

Th = 270 Klb at TD

Margin of over pull = 392 – 270 = 122 Klb

Safety Factor = 392 ÷ 270 = 1.45

Ref Book:  Formulas and Calculations for Drilling, Production and Workover, Second Edition

Formulas and Calculations for Drilling, Production and Workover, Second Edition